Optical components required for laser welding

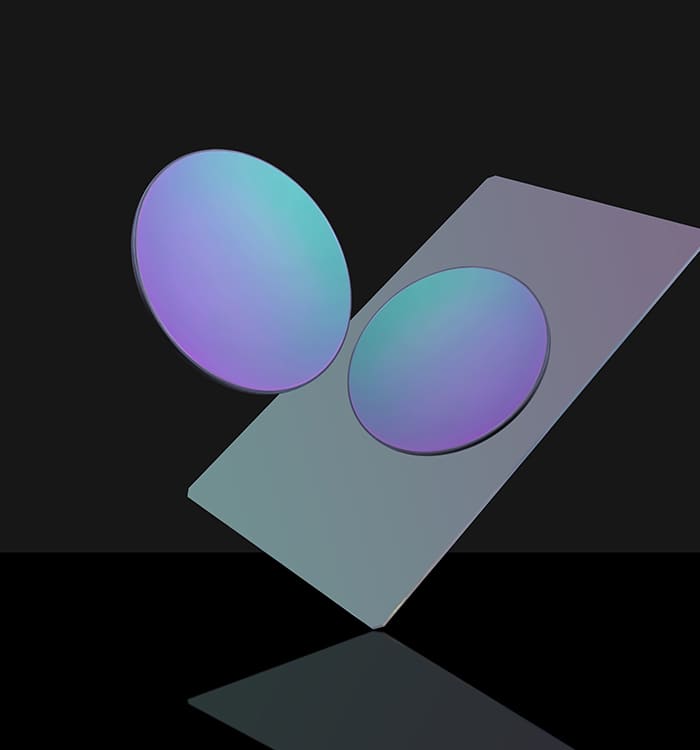

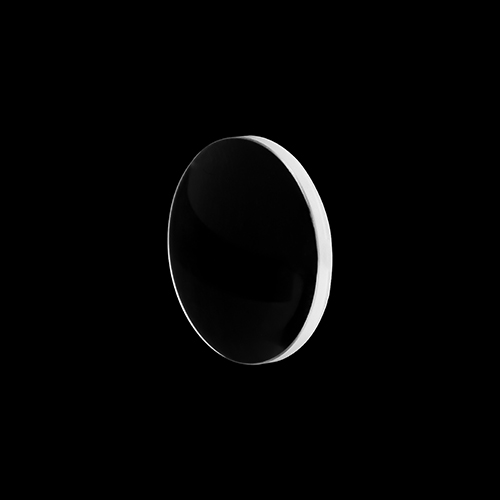

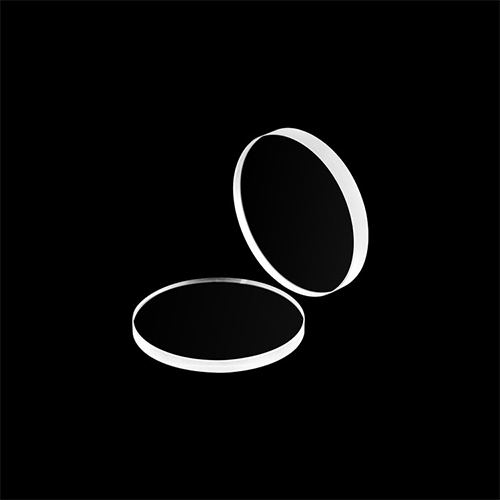

Windows

Calcium fluoride windows, barium fluoride windows, magnesium fluoride windows, silicon windows, germanium windows, zinc selenide windows, zinc sulfide windows, sapphire windows, fused silica windows, lithium fluoride windows, K9 glass windows

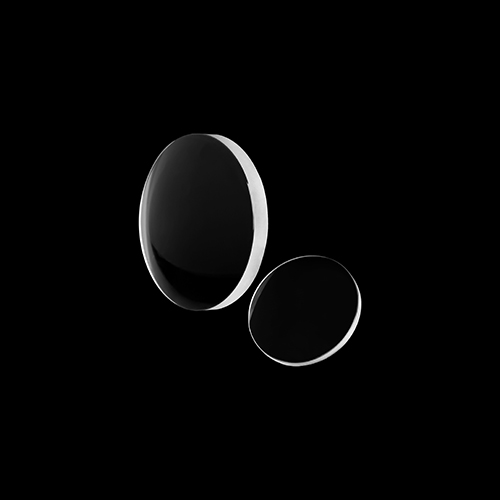

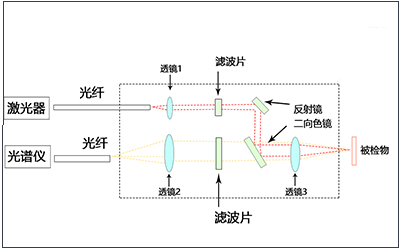

Lens

planar convex lens, planar concave lens, biconvex lens, biconvex lens, meniscus lens

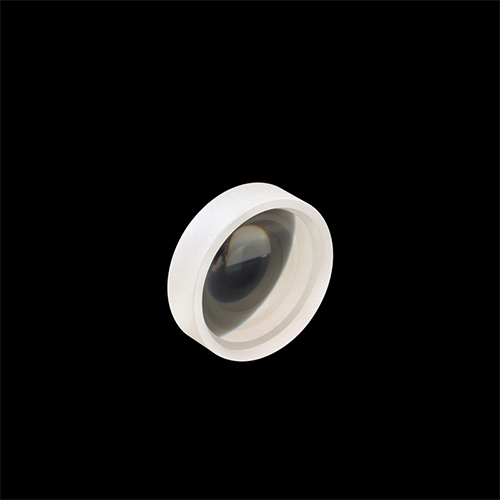

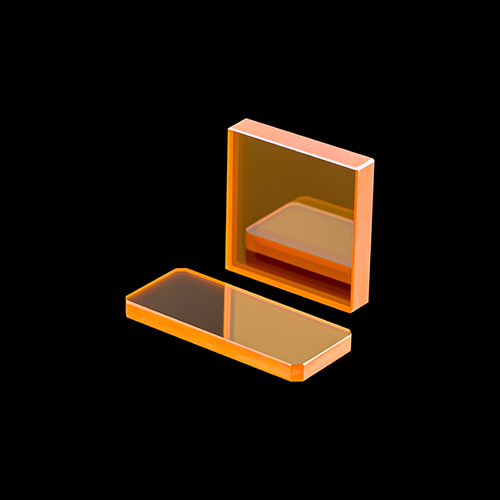

Filters

Germanium long wave pass filters, silicon long wave pass filters

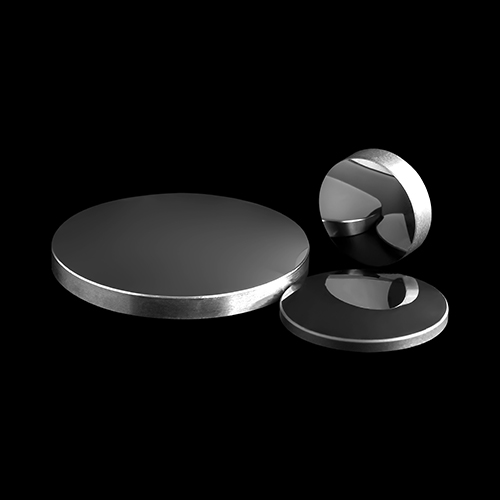

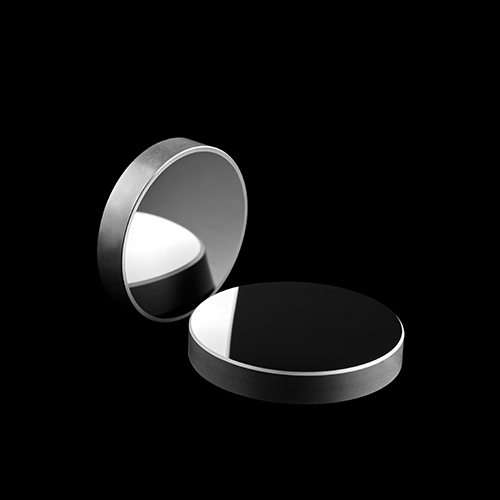

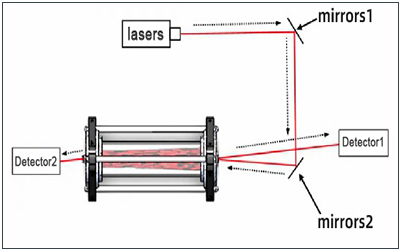

Mirrors

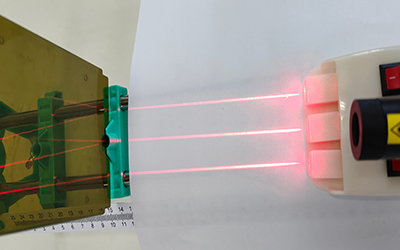

Application fields of laser welding

Automotive manufacturing, aerospace, electronic assembly, medical device manufacturing, jewelry industry, machinery manufacturing, construction, shipbuilding, petrochemical industry

Instruments required for laser welding

Laser generator, optical oscillator, fiber laser welding machine pulse laser power supply, fiber transmission system, specialized cooling system, industrial TV observation system, radiation parameter sensor, process medium conveying system, process parameter sensor