In the field of material science, calcium fluoride and fused silica are both materials of great concern. They are widely used in various industrial and scientific fields due to their unique physical and chemical properties. Among them, hardness, as one of the basic properties of materials, is of great significance for evaluating their performance in use. So, which is harder, calcium fluoride or fused silica?

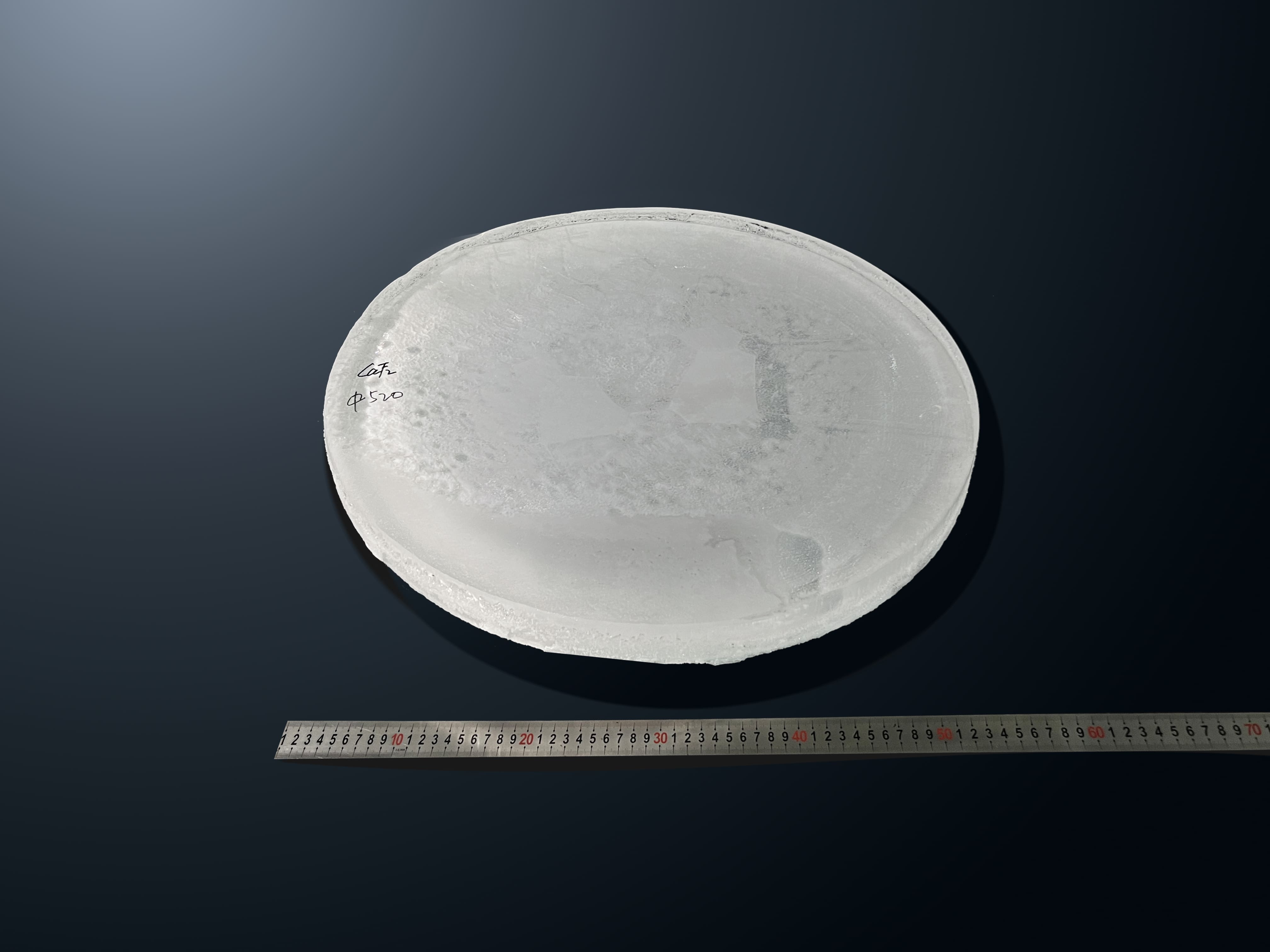

Calcium fluoride material is called fluorite, which is a colorless crystalline or white powder. It has a high refractive index and is therefore widely used in the field of optics. In addition, calcium fluoride also has a high hardness, and its hardness value can be comparable to glass in some aspects. This makes calcium fluoride widely used in the manufacturing of optical components, lenses, and windows.

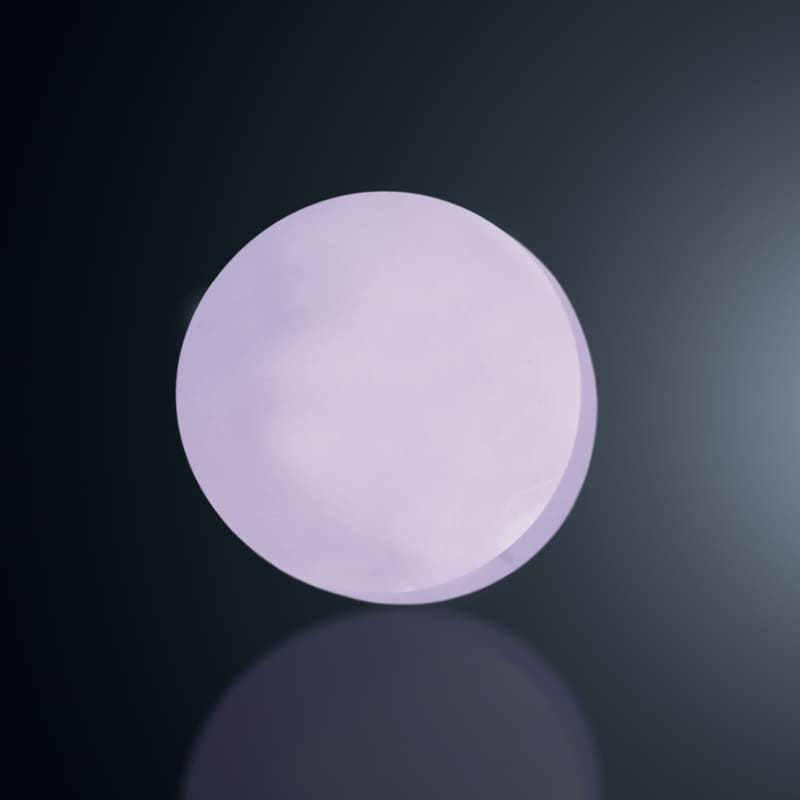

Fused silica material is called fused silica glass, which is a kind of material fused from high-purity silicon dioxide. It has extremely high transparency, low coefficient of thermal expansion, and good chemical stability, making it widely used in fields such as optics, electronics, and semiconductors. The hardness of fused silica is also quite high, especially at high temperatures.

However, it is not easy to accurately compare the hardness of calcium fluoride material and fused silica material. Because hardness is a relative concept, it is influenced by various factors such as the crystal structure of the material, the type of chemical bonding, purity, etc. In addition, different testing methods and standards may also lead to differences in hardness values.

In practical applications, we usually need to choose suitable materials based on specific usage environments and requirements. For example, in situations where high transparency and high refractive index are required, calcium fluoride may have more advantages; However, fused silica may be more suitable for applications where high stability and low coefficient of thermal expansion are required.

To sum up, both calcium fluoride materials and fused silica materials have high hardness, but which is harder depends on the test method and use conditions. When selecting materials, we should comprehensively consider their performance indicators such as hardness, transparency, stability, etc. to meet the needs of practical applications. With the continuous development of science and technology, it is believed that the applications of these two materials in their respective fields will be further expanded and optimized.

The above is the harder answer to the calcium fluoride material and fused silica material. I hope it will be helpful to you. If you have any questions, please consult online or leave a message.