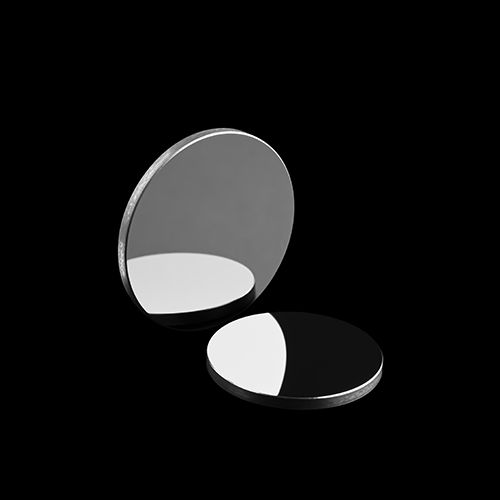

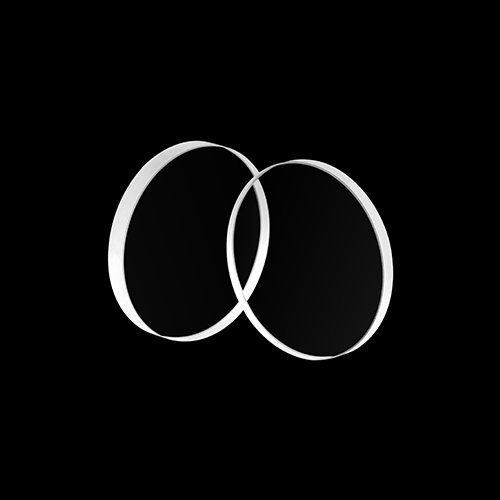

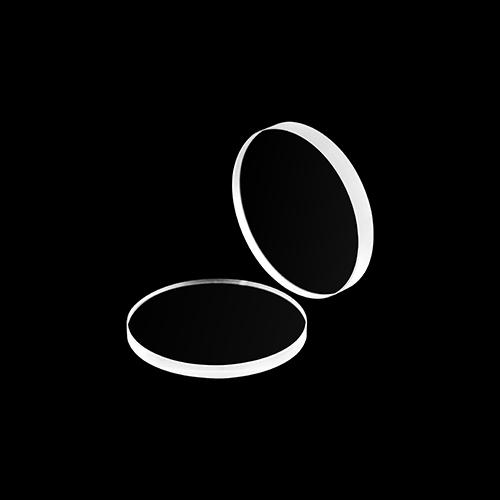

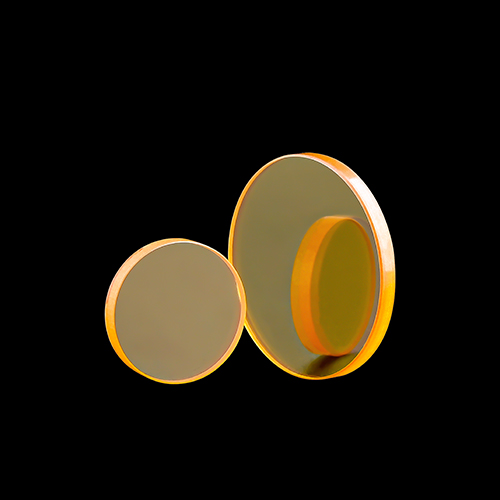

Calcium fluoride (CaF ₂) window is one of the commonly used optical components in Fourier transform infrared spectroscopy (FTIR) technology. With its unique physical and chemical properties, it has significant advantages in specific application scenarios, but also has certain limitations. The following analysis will be conducted from two aspects: advantages and disadvantages.

advantage

Broad spectral translucency

The transparency range of calcium fluoride window covers from ultraviolet (0.13 μ m) to mid infrared (about 10 μ m), and is compatible with multi band experiments of ultraviolet visible infrared, making it suitable for complex spectral analysis.

Excellent water resistance

Unlike deliquescent materials such as potassium bromide (KBr), calcium fluoride has high stability in humid environments and can be directly used for the detection of aqueous samples (such as biological fluids and cell culture media) to avoid signal interference caused by moisture absorption.

Biocompatibility

Its chemical properties are mild and do not react significantly with biomolecules, making it suitable for biomedical fields such as in vivo tissue analysis or drug protein interaction research.

Moderate chemical stability

Stable performance in weak acid, neutral or alkaline environments, convenient surface cleaning, low maintenance costs, suitable for routine laboratory use.

disadvantage

Not resistant to strong acid corrosion

Calcium fluoride is easily corroded by strong acids such as hydrochloric acid and sulfuric acid, and cannot be used for monitoring corrosive chemical reactions. It needs to be replaced with zinc selenide (ZnSe) or sapphire window plates.

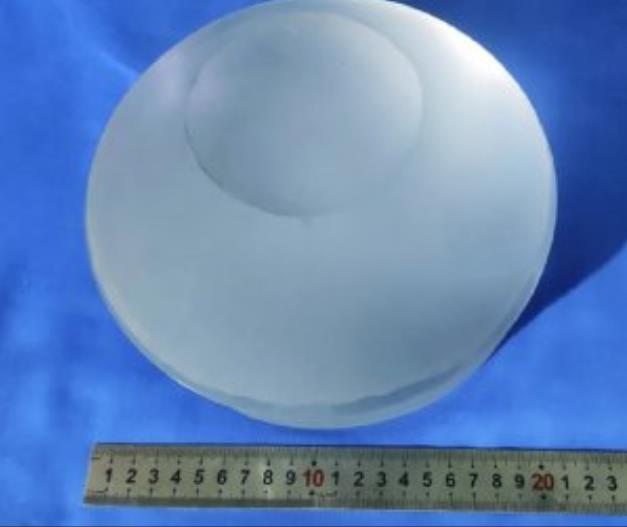

Low mechanical strength

The Mohs hardness is only level 4, with poor wear resistance. Long term use may result in scratches, affecting light transmission efficiency and detection accuracy.

Insufficient far-infrared performance

The transmission range rapidly decays in the far-infrared region (>10 μ m), which cannot support far-infrared spectral analysis. It needs to be used in conjunction with window plates made of materials such as polyethylene (PE).

Limited high-temperature tolerance

The working temperature is usually below 300 ° C, and it is prone to cracking at high temperatures, making it unsuitable for monitoring high-temperature molten samples or industrial high-temperature reactions.