Zinc selenide (ZnSe), as an important optical material, is widely used in the manufacturing of various optical devices due to its high refractive index, high transmittance, and excellent performance in the infrared spectral range. So what are the optical processing techniques for zinc selenide crystals? Let's take a look together!

crystal growth

High quality zinc selenide single crystals need to be grown through appropriate methods. Common crystal growth methods include chemical vapor deposition (CVD), melt growth, and gas-phase transport. These methods can prepare large-sized and high-purity zinc selenide, providing high-quality raw materials for subsequent processing.

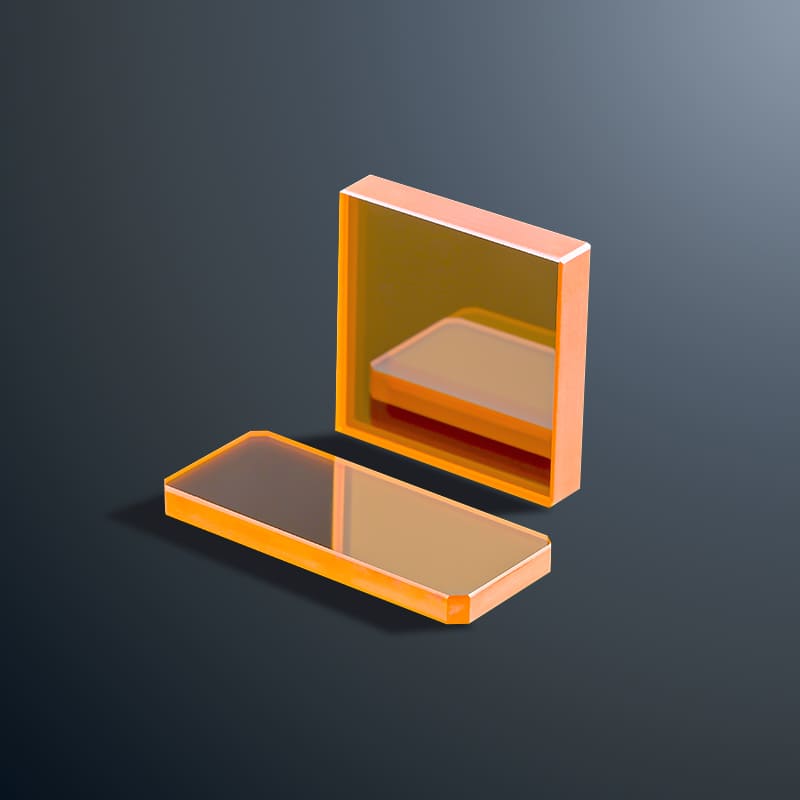

Cutting and rough machining

The grown zinc selenide crystals need to be cut into appropriate sizes and undergo preliminary rough processing such as grinding, sawing, etc. The purpose of this step is to process the crystal into a basic shape that meets the subsequent processing requirements.

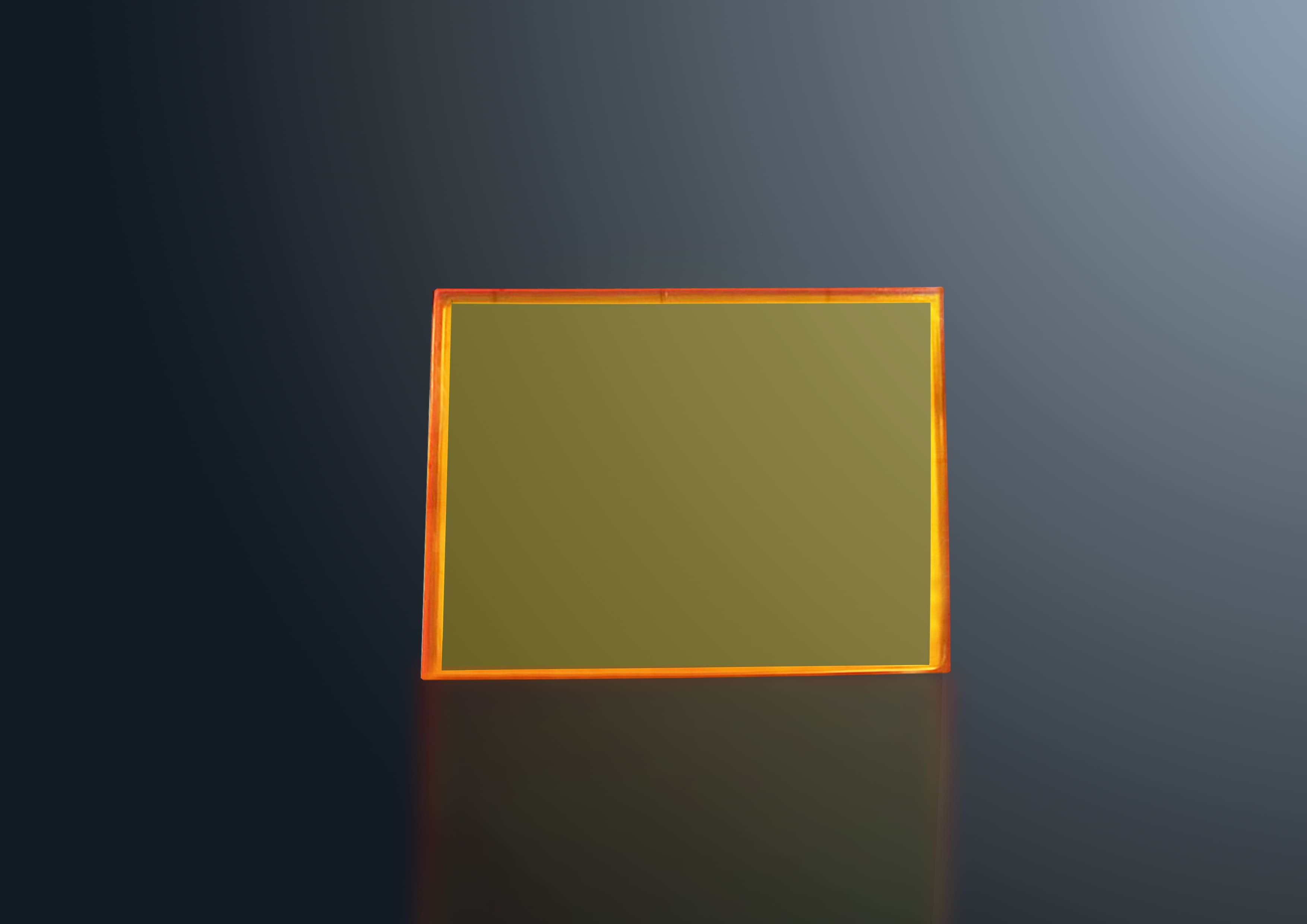

Flat polishing

On the basis of rough machining, fine optical plane polishing is carried out. On the basis of grinding, use polishing tools and agents to further smooth the surface and achieve the required optical surface quality.

Coating

Coating a specific optical film system on the surface of zinc selenide crystals to improve their optical properties or add other functions. For example, anti reflective film can be coated to increase the transmittance of optical components, or conductive film can be coated to improve their conductivity.

Detection and evaluation

During and after processing, it is necessary to test and evaluate the optical properties of zinc selenide crystals. This includes surface roughness measurement, refractive index measurement, transmittance testing, etc. Through these detection methods, it can be ensured that the processed zinc selenide optical components meet the design requirements and have excellent optical performance.

The above is the answer to the optical processing technology of zinc selenide crystals. We hope it is helpful to you. If you have any questions, please feel free to consult or leave a message online.