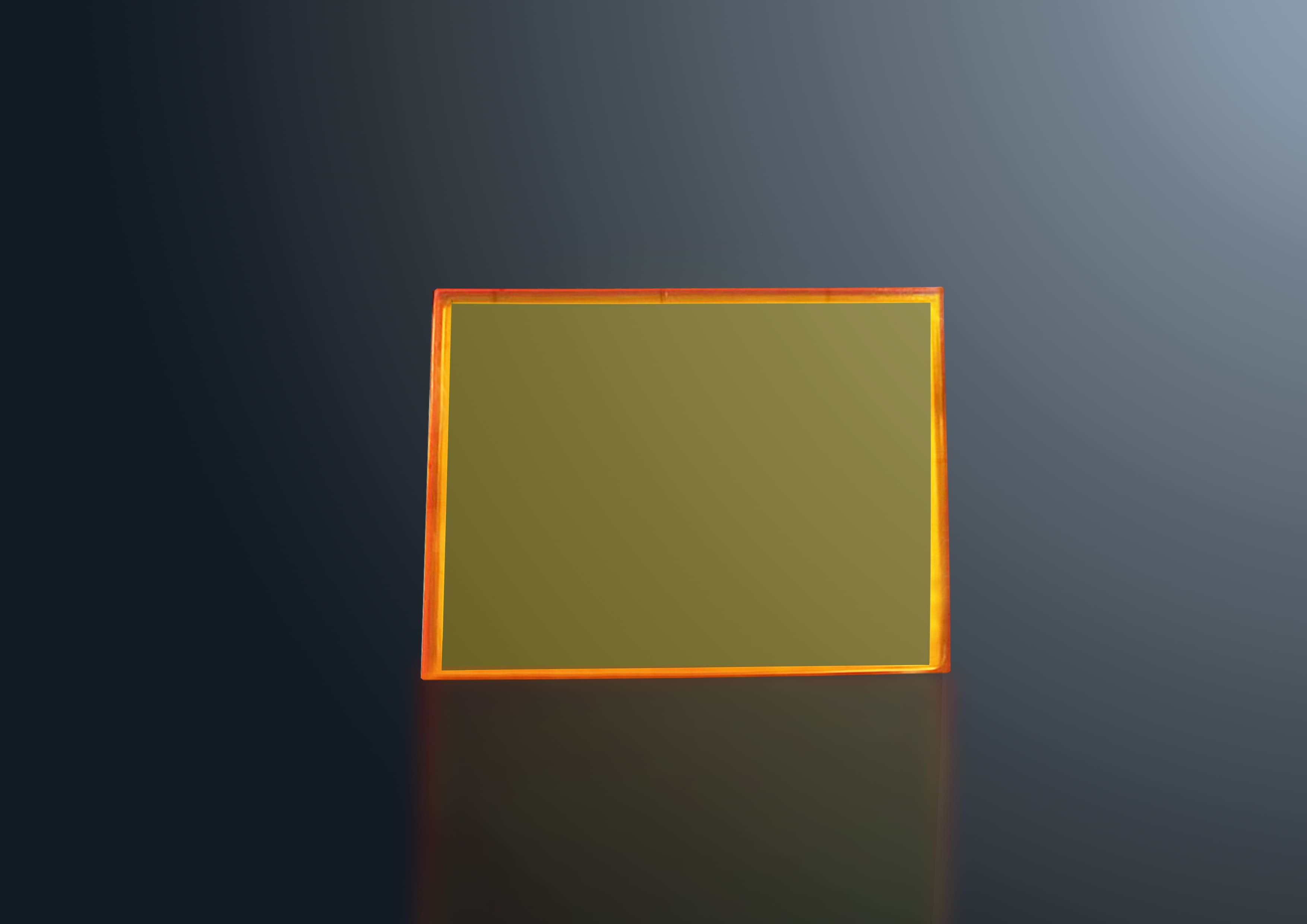

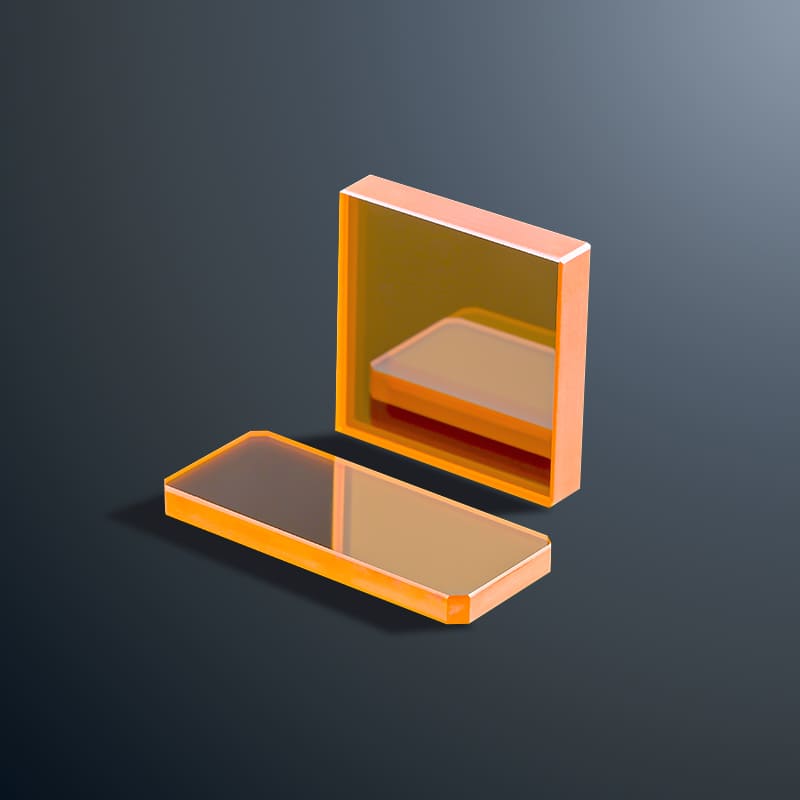

Zinc selenide (ZnSe), as a high-quality optical material, has a wide range of applications in infrared optics, optoelectronic devices, and other fields. In the processing of zinc selenide, polishing is a crucial step, as it determines the final optical properties and quality of the material. So, what is the polishing process for zinc selenide? Let's take a look together!

Coarse grinding

Use coarse grinding tools and abrasives to preliminarily grind the surface of zinc selenide to remove large particle impurities and uneven parts on the material surface. The main purpose of this step is to provide a relatively flat surface for the subsequent polishing process.

Fine grinding

After rough grinding, use finer grinding tools and abrasives for further grinding. The purpose of this step is to remove scratches and unevenness left during the rough grinding process, gradually making the surface smoother.

polishing

On the basis of fine grinding, use polishing tools and polishing agents to polish the surface of zinc selenide. During the polishing process, the polishing agent rubs against the surface, removing fine scratches and unevenness to achieve the desired smoothness. The selection of polishing agents and control of polishing processes are crucial for the final optical performance.

Cleaning and drying

After polishing, it is necessary to clean the surface of zinc selenide to remove residual polishing agent and impurities. After cleaning, dry the material to ensure a clean and moisture free surface.

During the polishing process, it is necessary to strictly control the processing parameters, such as grinding and polishing pressure, speed, time, etc., to avoid surface damage caused by excessive processing or poor surface quality caused by insufficient processing. In addition, the selection of polishing tools and polishing agents is also crucial, as they directly affect the polishing effect and the optical properties of the material.

The above is an answer to the polishing process of zinc selenide. We hope it is helpful to you. If you have any questions, please feel free to consult or leave a message online.