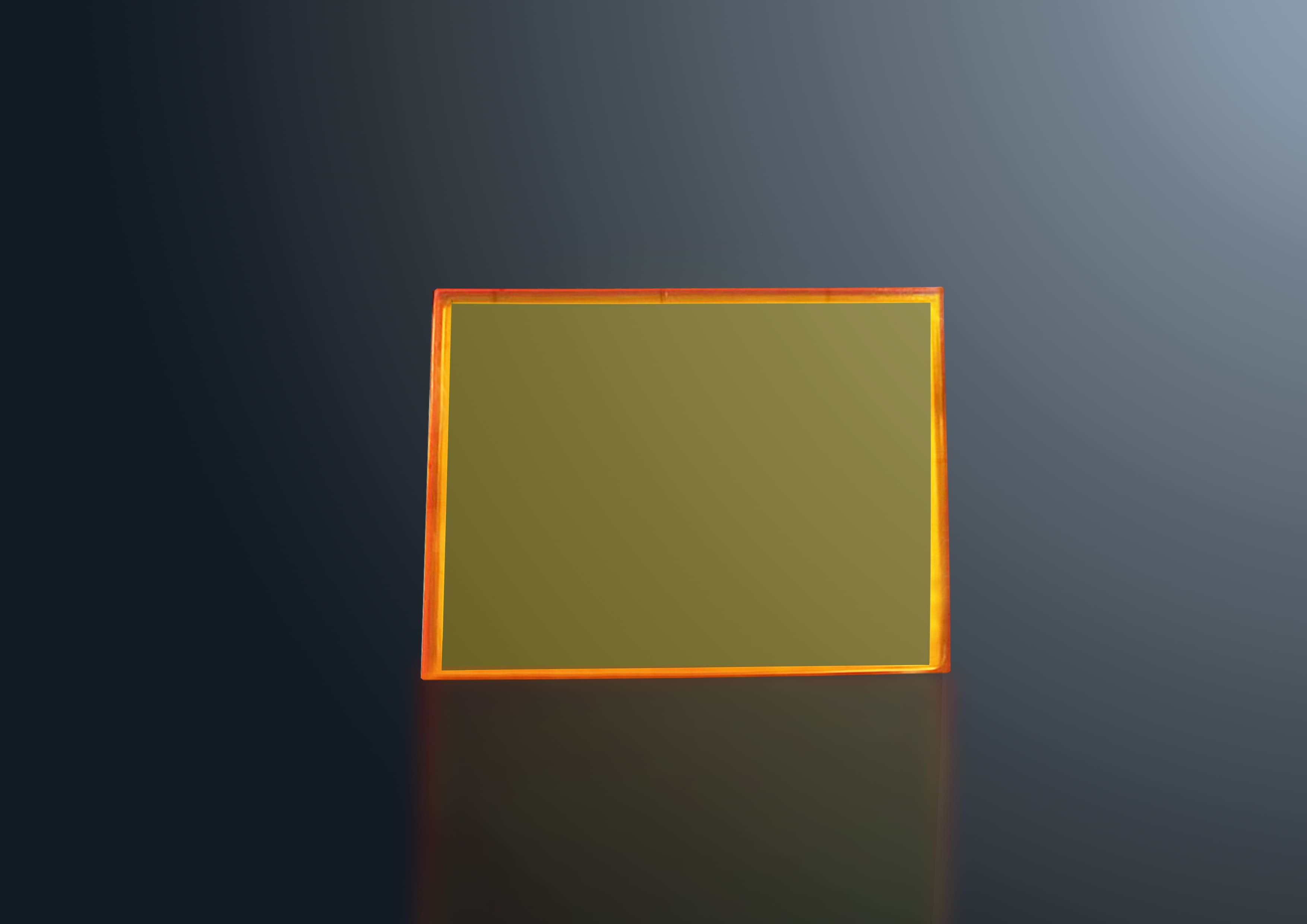

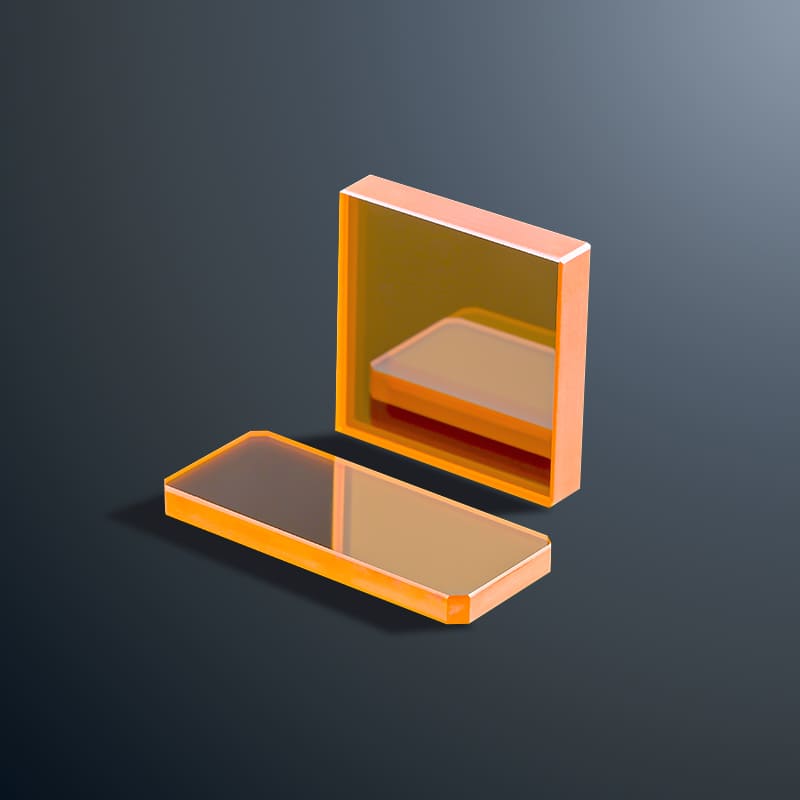

Zinc selenide, with the chemical formula ZnSe, is widely used in optoelectronic devices, solar cells, infrared optics, and other fields due to its excellent optical and electrical properties. Polishing is a crucial step in the processing of zinc selenide, as it can improve the surface smoothness and flatness of the material, providing a better foundation for subsequent applications. So, what excipients are needed in the zinc selenide polishing process?

The commonly used auxiliary materials in the zinc selenide polishing process include polishing solution and polishing pad. Polishing fluid is the core auxiliary material in the polishing process, mainly composed of abrasives, solvents, and additives. Abrasive is the main component in polishing solution, responsible for removing small protrusions and defects on the surface of zinc selenide, making its surface smoother. Commonly used abrasives include alumina, silicon carbide, etc. The solvent is used to dilute abrasives and additives, so that the polishing solution can be evenly applied to the surface of zinc selenide. Additives are used to adjust the pH value, surface tension, and other properties of the polishing solution to improve the polishing effect.

Polishing pads are another important auxiliary material in the polishing process. The polishing pad is usually made of soft fabric or foam material, which is used to carry the polishing fluid and provide proper polishing pressure. The selection of polishing pads should be determined based on factors such as the hardness and surface roughness of zinc selenide, to ensure that small protrusions and defects on the material surface can be uniformly removed during the polishing process.

In addition to polishing fluids and pads, some auxiliary equipment such as polishing machines and cleaning equipment may also be used during the zinc selenide polishing process. The polishing machine is used to provide appropriate polishing pressure and speed, so that the polishing fluid and polishing pad can effectively remove defects on the surface of zinc selenide. The cleaning equipment is used to remove impurities such as polishing fluid and abrasives remaining on the surface of zinc selenide after polishing, to ensure the cleanliness of the material surface.

The above is the answer to what excipients are used for zinc selenide polishing. We hope it is helpful to you. If you have any questions, please feel free to consult online or leave a message.