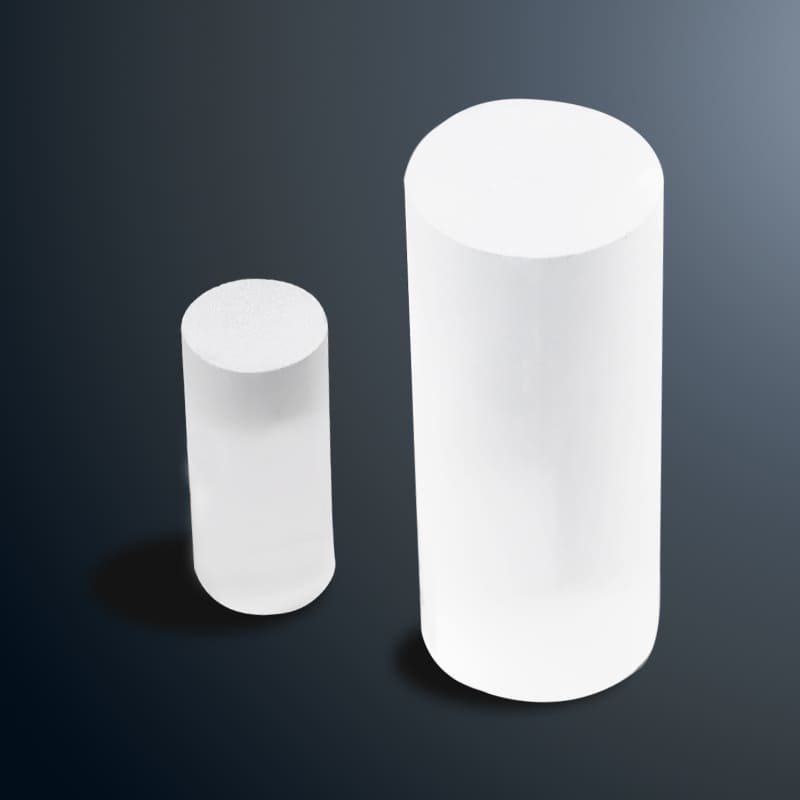

Barium fluoride crystals, as an important optical material, have been widely used in many fields due to their excellent optical properties. However, during production, processing, and use, scratches, defects, or unevenness are inevitable on the crystal surface, which not only affects its aesthetics but may also damage its optical performance. Therefore, polishing technology plays a crucial role in the preparation of barium fluoride crystals.

The importance of polishing process

Polishing is the final step in the processing of barium fluoride crystals, with the aim of removing small surface irregularities and scratches to achieve a smooth, transparent, and flawless state on the crystal surface. This not only improves the optical performance of the crystal, but also helps to extend its service life.

Polishing process steps

1. Pre treatment: Before starting polishing, the surface of the crystal should be cleaned to remove oil, dust, and other impurities from the surface. This can be achieved using appropriate solvents and cleaning tools.

2. Coarse grinding: Use a coarse grinding agent and polishing tool to preliminarily grind the surface of the crystal to remove large scratches and unevenness. In this step, attention should be paid to controlling the grinding force and grinding time to avoid surface damage caused by excessive grinding.

3. Fine grinding: After rough grinding, use finer abrasives and polishing tools to further grind the crystal surface to remove smaller scratches and unevenness. More precise control of grinding force and time is required in this step to obtain a smoother surface.

4. Polishing: Finally, use polishing solution and polishing cloth or polishing wheel to polish the surface of the crystal to obtain a highly smooth and transparent surface. During the polishing process, attention should be paid to controlling the polishing force and the amount of polishing fluid used to achieve the best polishing effect.

Polishing tools and materials

Choosing the appropriate polishing tools and materials during the polishing process is crucial for achieving high-quality polishing results. Common polishing tools include polishing wheels, polishing cloths, and polishing brushes. And polishing materials include abrasives, polishing liquids, and cleaning agents, etc. The selection of these tools and materials should be determined based on the characteristics of barium fluoride crystals and polishing requirements.

Inspection after polishing

After polishing, strict inspection of barium fluoride crystals is required to evaluate the polishing effect. This can be observed through instruments such as optical microscopes and interferometers to observe the microscopic morphology and flatness of the crystal surface. At the same time, the optical properties of the crystal, such as refractive index, transmittance, etc., can also be tested to ensure that it meets the requirements for use.

The polishing process of barium fluoride crystals is a key step in ensuring the surface quality and optical properties of the crystals. Through reasonable polishing steps, appropriate selection of polishing tools and materials, and strict post polishing inspection, high-quality barium fluoride crystal surfaces can be obtained, providing strong support for their applications in optical, electronic, and ceramic fields.

The above is an answer to the polishing process of barium fluoride crystals. We hope it is helpful to you. If you have any questions, please feel free to consult or leave a message online.