Laser film, also known as laser film or laser holographic film, is a thin film material with special optical effects. So what are the differences between laser films and fiber optic films?

Definition and purpose

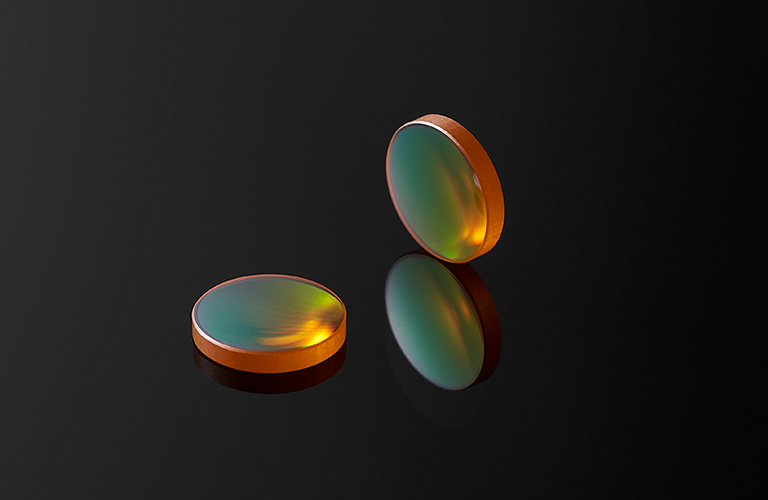

Laser film: It is a specially designed film used in laser cutting processes to protect cutting materials, improve cutting quality and efficiency. Applied to laser cutting protection of stainless steel plates, such as 8K, wire drawing, frosting, sandblasting, vacuum titanium plating, water plating, painting, transfer printing, etc.

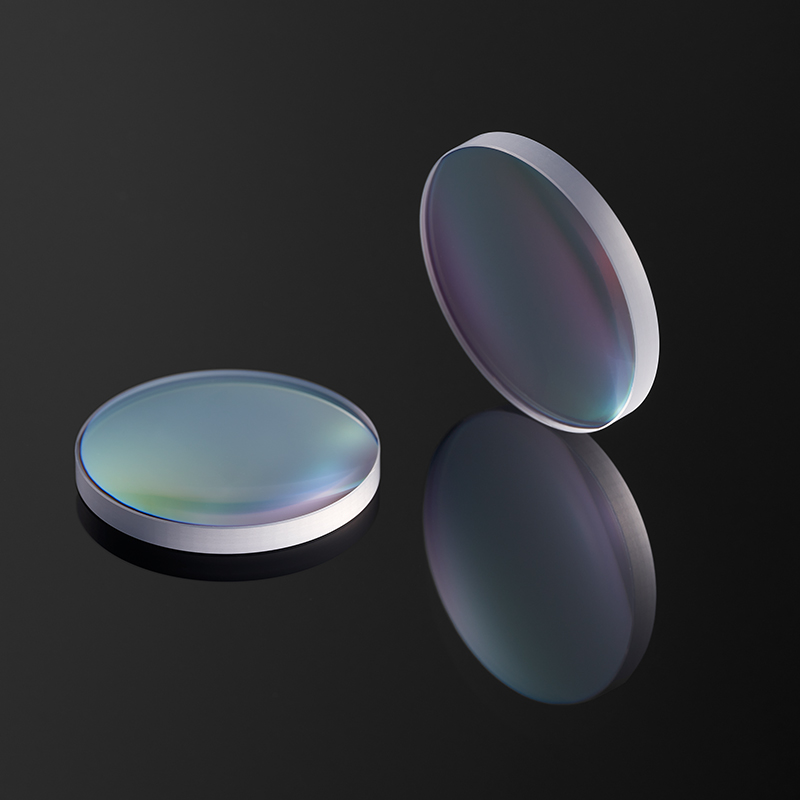

Fiber optic membrane: It is a green and environmentally friendly consumable used in facilities, aquaculture, biochemistry, pharmaceuticals, petroleum exploration, papermaking and mining industries. Fiber coating specifically refers to coating multiple layers of high-precision optical thin films on the fiber head to reduce the reflectivity of the fiber end face or achieve wavelength selective transmission and reflection. It is often used for machine coating.

Performance characteristics

Laser film

High energy laser transmission characteristics: effectively absorb laser power, avoiding the generation of smoke and dust during cutting.

Temperature resistance: withstands high temperatures, is antioxidant, UV resistant, does not deform, and does not change color.

Optical properties: It can absorb the energy of the laser into the film, improving cutting quality and efficiency.

Service life: Long, stable effect after repeated use.

Film thickness and viscosity: The film thickness is usually between 70-100um, with a viscosity of 250-350g.

Fiber optic membrane

Acid resistant, alkali resistant, wear-resistant, and corrosion-resistant: it has excellent chemical stability.

Flexibility, antibacterial, and anti-static: possessing excellent physical properties.

Green and environmentally friendly: As a new generation of consumables, it meets environmental requirements.

The above is an answer to the differences between laser film and fiber film. We hope it will be helpful to you. If you have any questions, please feel free to consult or leave a message online.