Lithium fluoride, as an inorganic compound, plays an important role in glass manufacturing. So what are the functions of lithium fluoride in glass? Let's listen together!

Lithium fluoride used as a flux in glass manufacturing

Due to its low melting point, lithium fluoride can effectively reduce the melting temperature of glass, thereby simplifying the production process of glass. This melting aid not only improves production efficiency, but also reduces energy consumption, helping to achieve green and environmentally friendly production methods.

Lithium fluoride has a significant effect on improving the transparency of glass

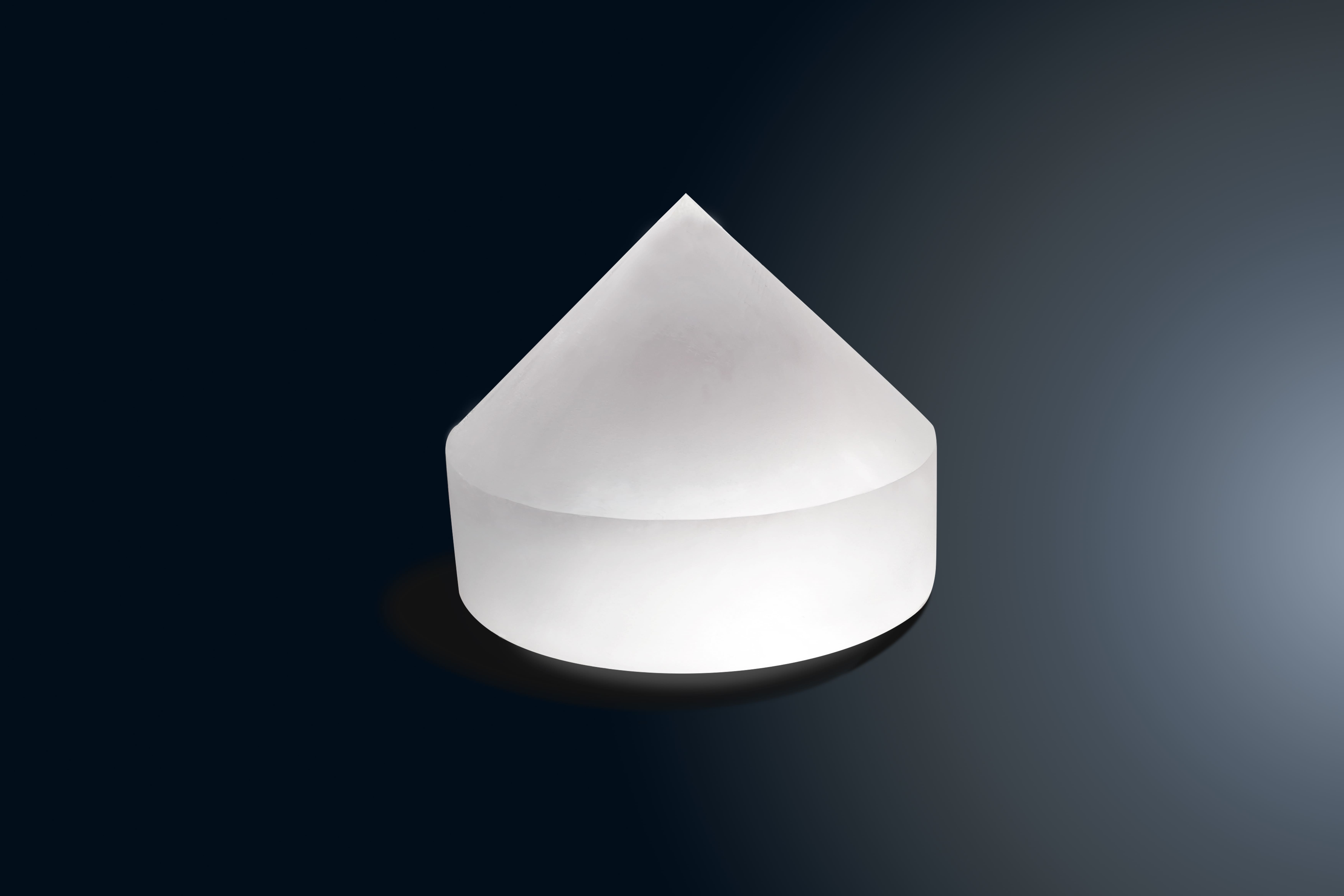

In the glass manufacturing process, the addition of lithium fluoride can effectively reduce bubbles and impurities in the glass, making it clearer and more transparent. This high-quality transparency makes lithium fluoride an ideal choice for manufacturing high-quality optical components, windows, and glasses.

Lithium fluoride is also widely used in the manufacturing of specific types of glass

For example, in optical glass, the high transmittance and low refractive index properties of lithium fluoride make it a key raw material for manufacturing high-quality optical components. These optical components are widely used in fields such as photography, medicine, and scientific research, bringing convenience to people's lives and work.

In addition to the aforementioned effects, lithium fluoride also plays a special role in certain types of glass. For example, lithium fluoride can be used as an additive in aluminum electrolysis and rare earth electrolysis processes to improve electrolysis efficiency and product quality. These special types of glass have broad application prospects in fields such as aerospace and electronic information.

The above is an interpretation of the role of lithium fluoride in glass. We hope it will be helpful to you. If you have any questions, please feel free to consult or leave a message online.